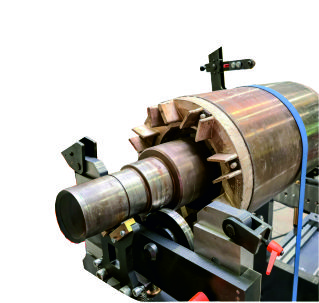

05 Dynamic balancing of electric motors, fans, turbines, etc.

We carry out the process in accordance with the PN-EN ISO 21940-11 standard, in accuracy classes G0.4 – G6.3, depending on the type and purpose of the rotor. This allows us to ensure precision suitable for both heavy industry and equipment with increased dynamic requirements.

Scope of service

We offer precise balancing of components with a wide range of parameters:– Rotors weighing from 0.5 to 50 kg – shaft journal diameters from 10 to 75 mm, length up to 2500 mm.

– Rotors weighing from 30 to 3,500 kg – shaft journal diameters from 20 to 125 mm, length up to 2,500 mm.

We offer:

- short lead time,

- vibration measurement and analysis,

- on-site imbalance correction,

- full measurement report documenting the correction results with balancing parameters.

It is worth weighing up because we get:

- longer service life of bearings and the entire drive system – lower loads mean slower wear and tear and less downtime,

- lower risk of damage and failure – reduced vibrations protect not only the machine itself, but also the environment, and in the case of large rotors, prevent potentially dangerous situations,

- less vibration and noise – improved comfort and safety throughout the plant,

- lower energy consumption – a well-balanced rotor runs more smoothly and efficiently,

- greater reliability and smoother operation of the machine – stable operation means less risk of errors and better production quality.

+48 618 798 609

+48 618 798 609 aret@aret.com.pl

aret@aret.com.pl